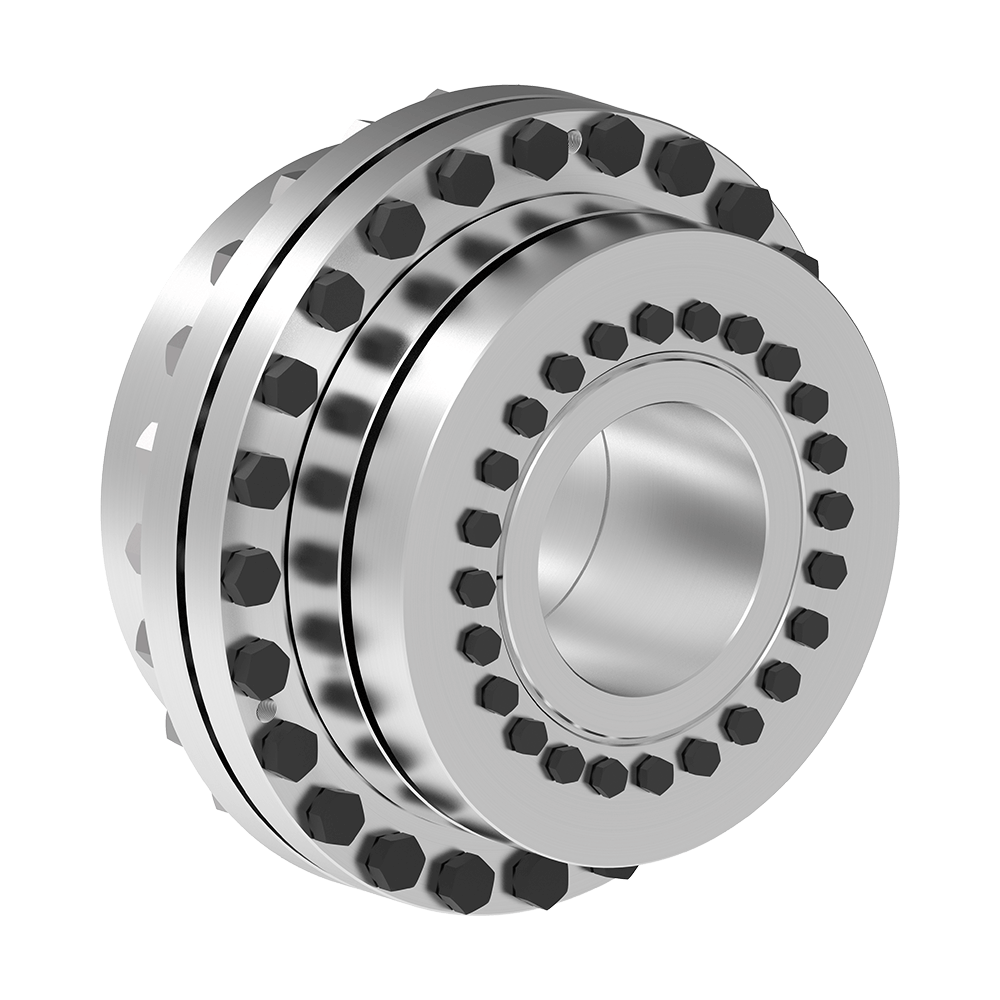

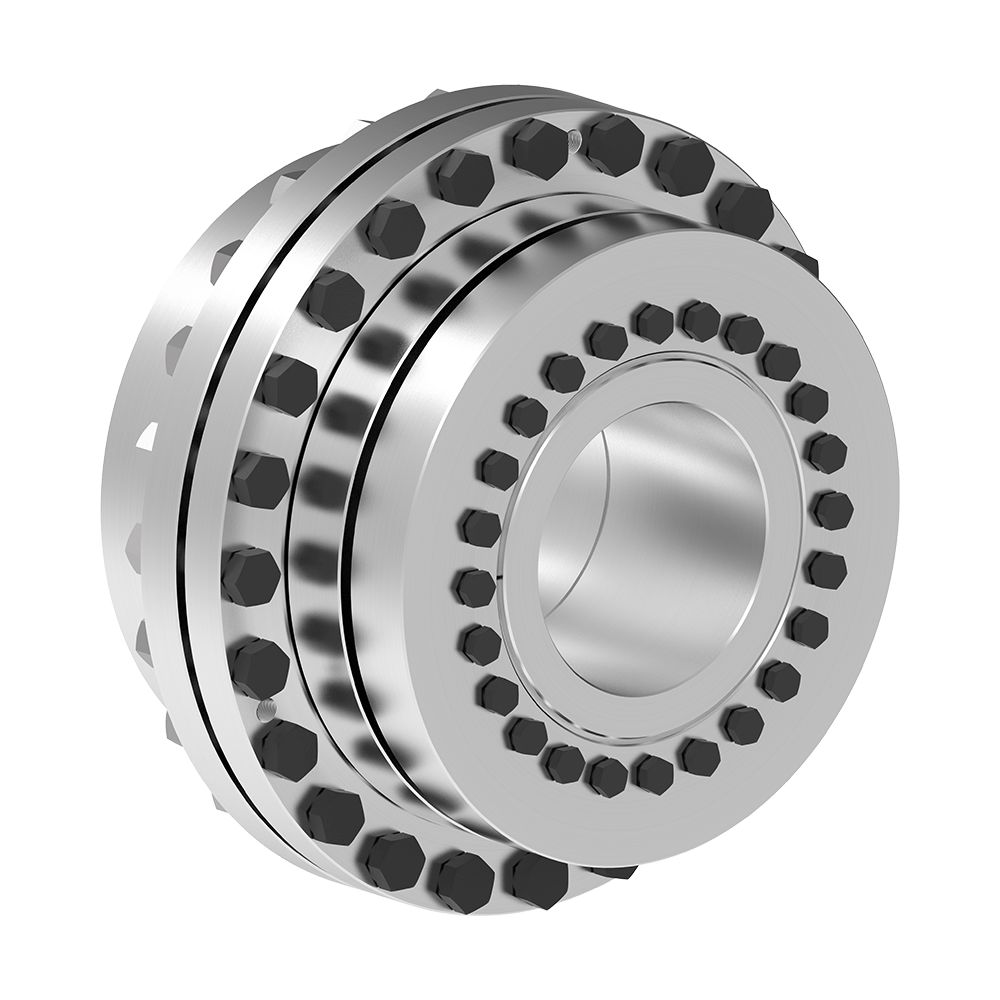

Flange Coupling

Product Details:

- Surface Finish Smooth

- Application Industrial

- Feature Corrosion ResistantHigh Wear Resistance: Suitable for high-volume production Precision Machining: Ensures consistent part dimensions Tough & Durable: Withstands extreme pressure and repeated use Custom Designs: Made to match part geometry and forming process Compatible with All Major Forging Presses

- Product Type Other

- Material Carbon Steel

- Standard DIN

- Shape Round

- Click to View more

Flange Coupling Price And Quantity

- 1 Piece

- 2000.0 INR/Piece

Flange Coupling Product Specifications

- Galvanized

- Black

- Male

- Hot Rolled

- Industrial

- DIN

- Carbon Steel

- Other

- Corrosion ResistantHigh Wear Resistance: Suitable for high-volume production Precision Machining: Ensures consistent part dimensions Tough & Durable: Withstands extreme pressure and repeated use Custom Designs: Made to match part geometry and forming process Compatible with All Major Forging Presses

- Smooth

- 2 Inch

- Round

Flange Coupling Trade Information

- Paypal, Cash Advance (CA), Cash in Advance (CID)

- 100 Piece Per Day

- 1 Week

- Yes

- Contact us for information regarding our sample policy

- Cartons , Wooden Crates , Plastic Bags , Bubble Wrap/ Foam:

- Asia

- All India

- Depending on the application (like in the food industry or pharmaceuticals), the product might carry certifications like FDA, NSF, or others.

Product Description

Product Title:

Cold Forging Die Precision Engineered for High-Performance Metal Forming

Product Description:

We are a reputed manufacturer and supplier of Cold Forging Dies, specially designed for high-speed and high-pressure metal forming operations. Manufactured using premium-grade tool steel and treated with advanced heat treatment processes, our dies ensure excellent wear resistance, dimensional accuracy, and extended service life.

Our Cold Forging Dies are widely used in the production of automotive components, fasteners, hardware items, and precision-engineered parts. We provide customized die designs as per customer drawings, samples, or technical requirements.

Key Features:

-

High Wear Resistance: Suitable for high-volume production

-

Precision Machining: Ensures consistent part dimensions

-

Tough & Durable: Withstands extreme pressure and repeated use

-

Custom Designs: Made to match part geometry and forming process

-

Compatible with All Major Forging Presses

Technical Specifications:

-

Material: D2, HCHCr, HSS, Carbide, or as specified

-

Hardness: 5862 HRC (after heat treatment)

-

Finish: Ground, Polished, or Mirror Finish (as required)

-

Tolerance: As per drawing or customer specification

-

Design Support: 2D & 3D CAD/CAM with simulation (optional)

Applications:

-

Cold Forging of Bolts, Nuts, Screws

-

Automotive & Aerospace Components

-

Electrical and Fastening Parts

-

Bearing and Bushing Forming

-

Precision Industrial Hardware Production

Why Choose Us?

In-house Die Design and Tool Room Facilities

CNC, EDM & VMC Machining Capabilities

High-Quality Raw Materials and Heat Treatment

Customization as per Drawing or Sample

Quick Turnaround and Nationwide Delivery

Packaging & Delivery:

-

Packaging Type: Wooden Box / Foam Protected / Rust-Proof Packaging

-

Minimum Order Quantity: As per size and type of die

-

Delivery Time: 720 Days depending on complexity

-

Payment Terms: 50% Advance / Balance Before Dispatch

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+