Thread Rolling Job Work

Price 500.0 INR/ Piece

Thread Rolling Job Work Specification

- Thread Size

- Customized as per requirement

- Corrosion Resistance

- Available as per requirement

- Work Type

- Thread Rolling Job Work

- Surface Finish

- Smooth and precise

- Quality Assurance

- Inspection and testing included

- Service Mode

- Offline

- Technique

- Thread Rolling

- Accuracy

- High dimensional precision

- Capacity

- Up to 100 mm diameter

- Application

- Industrial components, automotive, fasteners, bolts, studs

- Thread Profile

- Metric, UNC, UNF, BSP, customized profiles

Thread Rolling Job Work Trade Information

- Minimum Order Quantity

- 50 Pieces

- FOB Port

- MUMBAI

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Standard Packing Details for Thread Rolled Components

- Main Export Market(s)

- Central America

- Main Domestic Market

- All India

- Certifications

- Common Certifications for Thread Rolling Job Work

About Thread Rolling Job Work

Thread Rolling Job Work

Product Description:

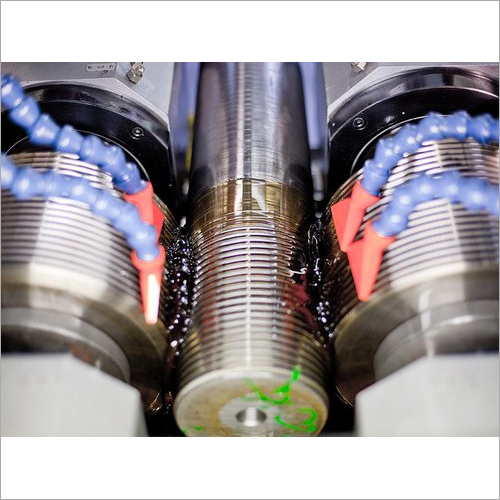

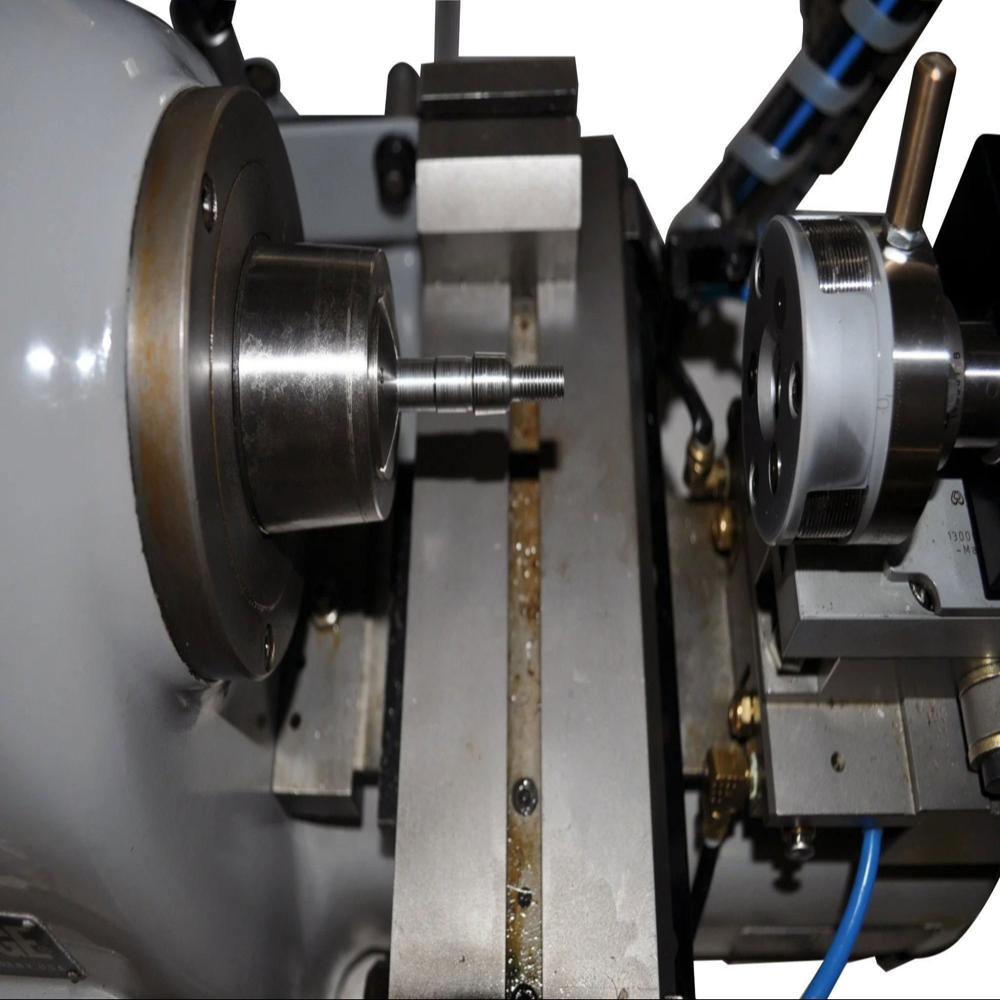

We offer expert Thread Rolling Job Work services for manufacturing high-quality threaded components used in various industrial applications. Our process ensures precise, strong, and durable threads on rods, shafts, bolts, and fasteners without any material removal, resulting in enhanced fatigue resistance and surface finish.

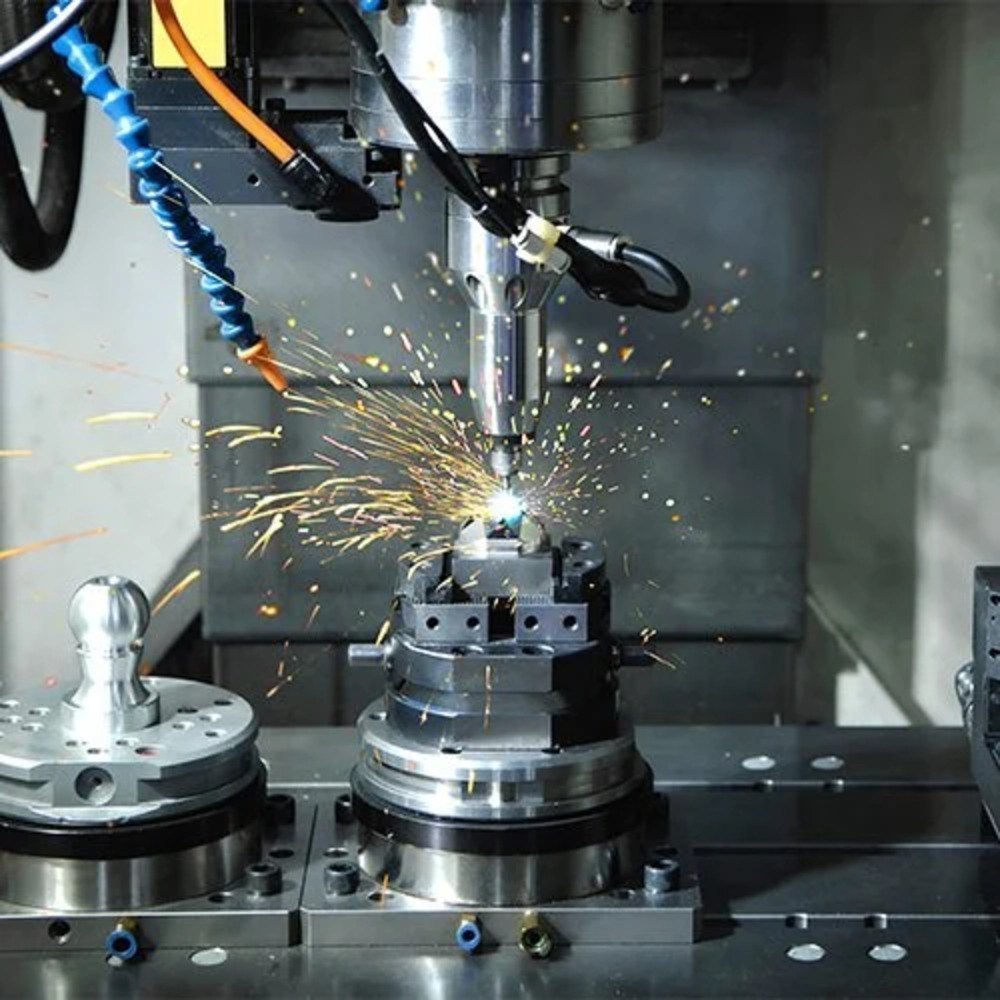

Using advanced thread rolling machines and skilled operators, we deliver consistent and accurate threads that comply with customer specifications and industry standards.

Service Highlights:

-

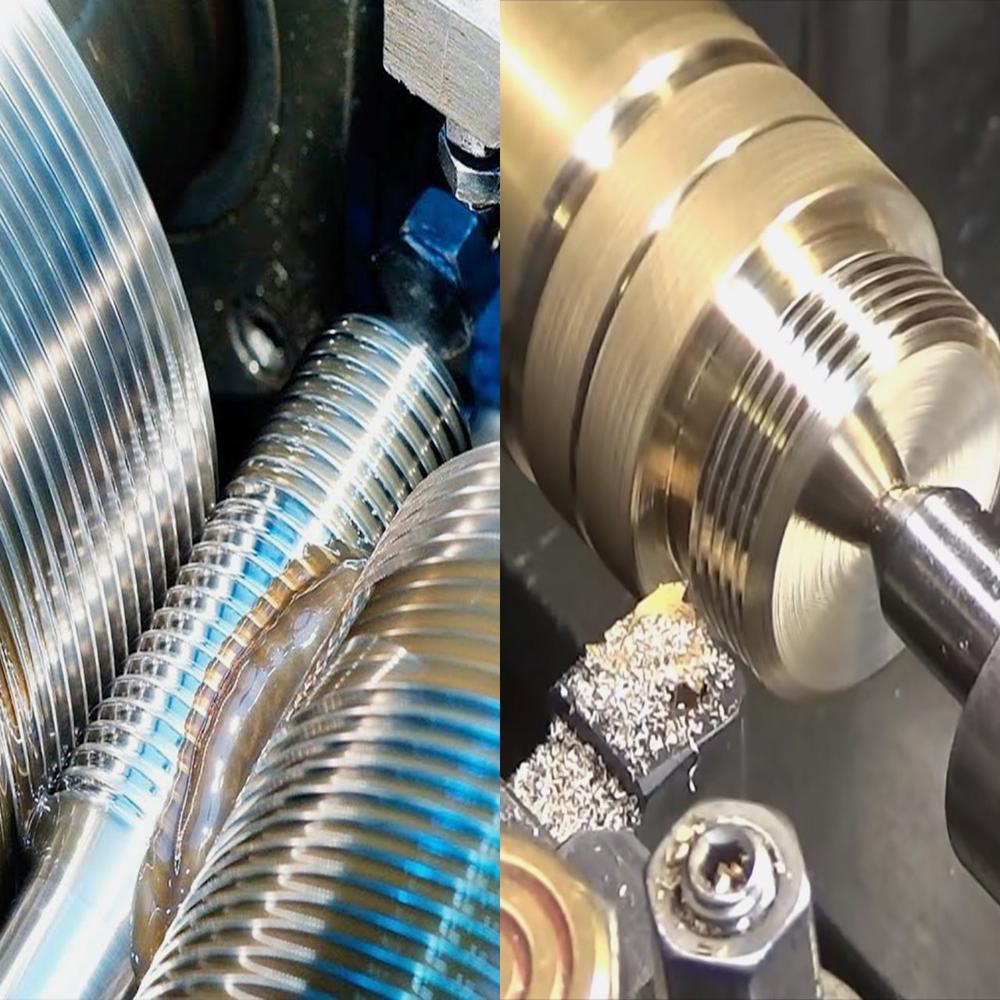

Types of Threads Rolled:

-

External Threads (Metric, UNC, UNF, BSP, etc.)

-

Multi-start Threads

-

Custom Thread Profiles as per drawings

-

-

Materials Handled:

-

Mild Steel (MS), Stainless Steel (SS), Alloy Steel

-

Brass, Aluminum, and other metals

-

-

Diameter Range:

-

3 mm to 50 mm (custom sizes available)

-

Length as per customer requirement

-

-

Advantages of Thread Rolling:

-

Increased thread strength & fatigue resistance

-

Smooth surface finish and no chip formation

-

Improved dimensional accuracy and thread consistency

-

Applications:

-

Automotive & Machinery Fasteners

-

Hydraulic & Pneumatic Components

-

Electrical Fittings

-

Construction & Engineering Parts

-

Custom OEM Components

Packaging & Delivery:

-

Components are cleaned and properly packed in anti-rust paper or polybags

-

Packed in sturdy cartons or wooden boxes based on order size

-

Timely dispatch with quality documentation

Service Location: [Your City, State]

Turnaround Time: 310 Days (based on order size)

MOQ: As per client requirement

Quality Assurance: Thread gauge checks and inspection reports provided

Why Choose Our Thread Rolling Job Work?

-

Skilled operators with extensive experience

-

Latest thread rolling machines for precision

-

Flexible batch sizes from prototypes to mass production

-

Competitive pricing and on-time delivery

-

Commitment to quality and customer satisfaction

Send us your drawings or samples for a detailed quotation today!

Precision Thread Rolling for Maximum Reliability

Experience tailored thread rolling with unmatched accuracy, suitable for customized and standard thread profiles. Utilizing modern thread rolling techniques, we handle diameters up to 100 mm, serving industries that demand high-quality finishes and durable threads.

Quality Assurance and Testing at Every Step

Each thread undergoes meticulous inspection and testing to ensure adherence to specified dimensions and performance. We offer corrosion-resistant options to enhance longevity, strictly following quality assurance protocols for every job.

Comprehensive Solutions for Multiple Industries

Our thread rolling services cater to a wide spectrum of industrial applications. Whether you need custom threading for automotive assemblies, fasteners, or heavy-duty bolts, our team leverages experience and advanced processes to meet diverse requirements effectively.

FAQs of Thread Rolling Job Work:

Q: How is the thread rolling process carried out in your job work?

A: We use precise thread rolling machines to cold-form threads onto workpieces up to 100 mm in diameter, ensuring consistent thread geometry and high dimensional accuracy. Our technique improves surface finish and strengthens thread integrity.Q: What types of thread profiles and sizes do you provide?

A: We offer Metric, UNC, UNF, BSP, and various customized thread profiles. Thread sizes are tailored as per your specific requirements to fit the diverse needs of industrial and automotive applications.Q: When should I consider thread rolling for my component production?

A: Thread rolling is ideal when your application demands high strength, smooth surface finish, and accurate threads. Its especially recommended for fasteners, bolts, and industrial components where durability matters.Q: Where do you provide your thread rolling job work services?

A: Our thread rolling job work is available across India, servicing manufacturers, suppliers, and industries seeking quality and precision in threading.Q: What quality assurance measures are implemented during thread rolling?

A: Every job includes thorough inspection and testing, with optional corrosion-resistant treatments provided as requested to meet application-specific standards and longevity.Q: How does using thread rolling service benefit my business?

A: Thread rolling enhances thread strength, provides superior surface quality, and ensures dimensional consistency. With customized solutions and comprehensive testing, you receive reliable components suitable for demanding industrial uses.Q: What are the main applications for your thread rolling services?

A: Our thread rolling services are widely utilized in producing fasteners, automotive components, industrial bolts, and studs, ensuring they meet stringent industry standards for performance and durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS